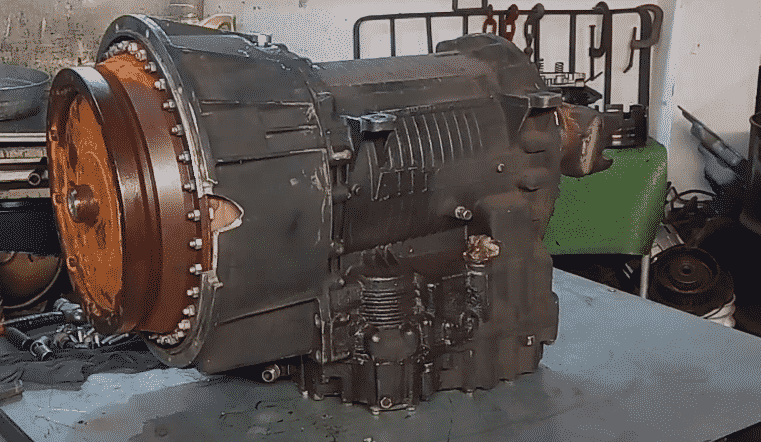

The Allison 10L1000 as it’s called, was developed by GM but with assistance from Allison engineers (and we’re told Allison actually performed much of the validation for the 10-speed). Beginning with ’20 model year HD trucks, the Allison boasted 10 forward speeds. In ’06 the Allison became a six-speed auto when it gained a second Overdrive (0.614:1). The Allison 1000 was dreamt up in the late 1990s and it brought a medium-duty work ethic to the light duty truck segment when it debuted behind the LB7 Duramax in ’01 model year Chevrolet Silverado and GMC Sierra HD’s. Whether you’re looking to preserve the life of your stock Allison or build it right the first time you pull it, you’ve come to the right place.

#Allison transmission problems plus

We’ll cover each of those failure points plus a few more this time, along with their appropriate aftermarket solution(s).

And at higher horsepower levels many have found out the hard way that the factory C2 hub and P2 carrier can fail catastrophically.

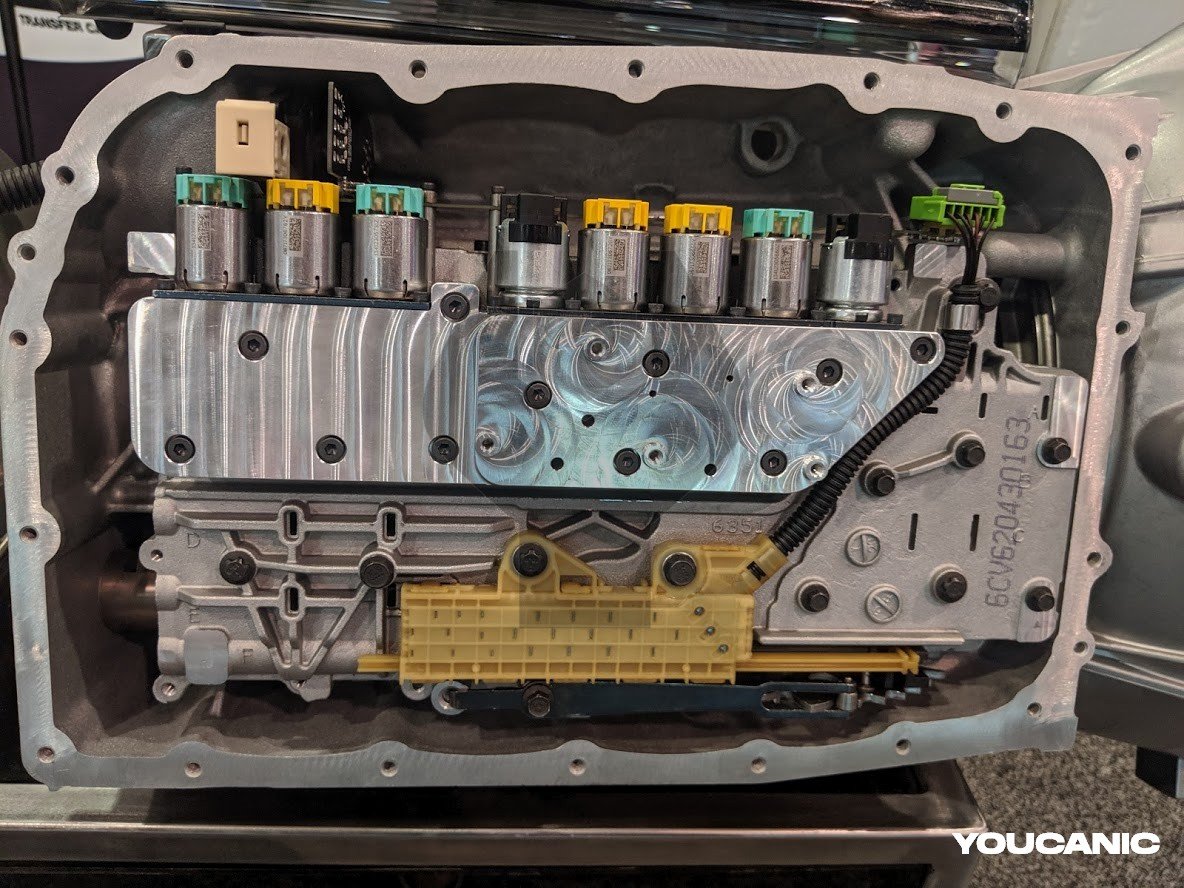

Clutch pack failures and slipping factory torque converters have perpetually been a weak link when the Duramax ahead of it has been turned up. Of course, it’s also no big secret that the commercial-grade Allison has its fair share of shortcomings, namely when it’s tasked with harnessing large increases in horsepower and torque. Since then, the Allison has gone from handling an input torque rating of 520 lb-ft to a mind-boggling 910 lb-ft at present, and chances are the current 10-speed rendition will be asked to grapple with even more in the future. The industrial-strength Allison 1000, with its 1.26-inch diameter input shaft, massive 1.75-inch output shaft, 12.2-inch diameter torque converter, and 330-pound heft was far superior to the 4R100 and 47RE available in the Ford and Dodge competition when it debuted in 2001. Every transmission is cold and hot tested before shipment.And The Aftermarket Parts That Address Themįor more than two decades, the Allison name has been synonymous with the Duramax, the common-rail, aluminum headed V-8 that put GM back at the forefront of the diesel pickup segment. ► Complete road simulation using a dynamometer testing program called C.A.R.S. Modifications include updates to servos, the PR system, and valve body accumulators. ► Complete system correction and recalibration kit installed to address several OE flaws. ► All new, bushings installed in key locations to improve internal fluid flow control and fluid pressures. Upgrades exceed OE requirements and eliminate the possibilities of front seal leaks, premature bushing wear, and vibration. ► Fully remanufactured torque converter is tested for leaks, lock-up, concentricity, and balance. ► Completely remanufactured late design pump with new line bore bushings eliminates leaks and provides superior flow and durability. ► Additional friction plate added to C3 clutch increases load capacity. ► E-Shift valve spring enhances shift quality and increases durability. ► F-Trim valve sleeve greatly reduces possibility of overheated torque converter. ► Upgraded lube regulator valve and torque converter relief spring eliminate delayed engagements and reduce operating temperatures. ► Late-OEM front pump covers eliminate cracking around torque converter pads.

►Fully remanufactured valve body, with complete system correction and recalibration kit, improves pressure control and shift quality.

0 kommentar(er)

0 kommentar(er)